Specifications

Available Sizes:

| Top | Body | Bottom |

| 1.20 | 1.20 | 1.20 (UN) |

| 1.20 | 1.0 | 1.20 |

| 1.0 | 1.0 | 1.0 (UN) |

| 1.0 | 0.9 | 1.0 (UN) |

| 1.0 | 0.8 | 1.0 (UN) |

| 0.8 | 0.8 | 0.8 (UN) |

Manufacturing Process:

Greif Hellas SA Operations ManualNominal Capacity:

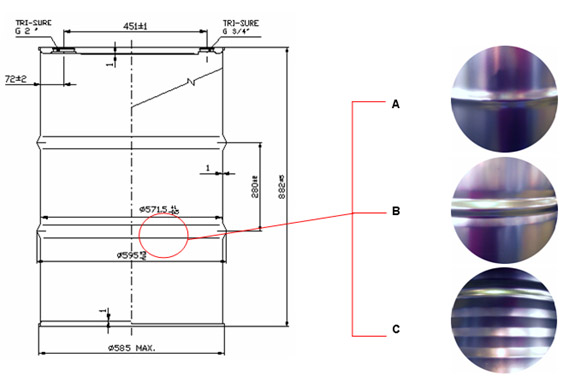

216.5 ltDrum Dimensions:

Attached Graph.-

- Steel Sheet quality according to FePO 1 Am (European Norm ΕΝ 10130 ) equivalent to SΤ 12 03 (German Norm DIN 1541)

- Steel Thickness variations +- 0.07 mm , according to EΝ 10131.

Drum Seaming:

- Body Welding: The two sides of the steel sheet are welded together with high Voltage Electric Current.

- Triple seaming Body with Bottom SPIRALON

- In between the bottom and the body there is material for portioning and insulation

Quality checks in the production

- Raw Materials quality controls

- Dimensions checks according to EN

- Leakages test by inserting high pressure air

The above checks are described in detail in the operations manual as it is described in the ISO 9002 certificate - Every 6 months randomly selected T.H. drums , are subjected to destruction tests to check the quality of the drum. (For drums that are approved according to UN regulations)

F.D.A. – Status:

Among the important features, Group's internal drum linings are formulated to meet the requirements for "Resinous and Polymeric Coatings" of F.D.A. Regulations, paragraph and section F175.300

Conclusion – Migration:

The stoving paint, coded RDL 06 and RDL 39 meet the requirements as mentioned in the European Guidelines 2002/72/EEC and 2004/13/EEC

Date of Approval

5/2005